Steering rods – why so many problems

27 October 2016

Self-adjusting clutch – Special Requirements

27 October 2016Hercula – service handle

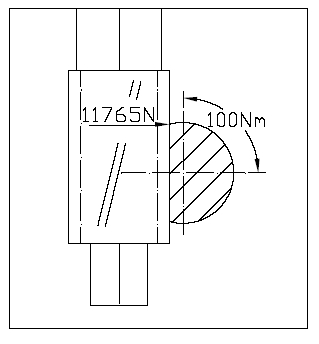

When replacing the steering rod in gearboxes with gear racks, there is often damage as a result of overloads of racks and bearing due to the forces arising from the torque required to loosen or tighten the rod.

The concentrated forces, with values as high as 1000 kG (10,000 N) – Fig. 1 cause:

- damage to the play-regulating system which causes the gearbox to knock,

- chipping of the gear rack and the steering shaft,

- damage to the lower steering shaft bearing,

- damage to the pressure seal in hydraulic assisted gearboxes,

- damage to the electronic steering torque sensor in gearboxes with electric assisted gearboxes.

Many car manufacturers require that rod replacements take place after removing the gearbox from the car.

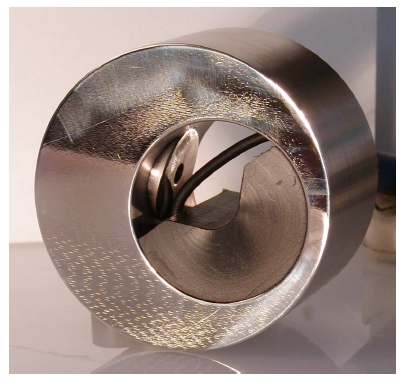

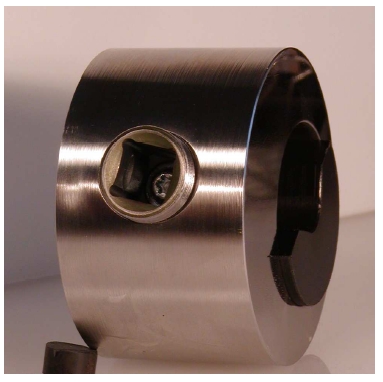

The presented service handle Hercula 02B is a universal tool for steering gears in cars and vans. The tool and its application are shown in the photos.

The tool is mounted on the rack and fixed by tightening the screw with a square ½’ socket.

Depending on the car type and the available space, blocking of the rack rotation is carried out via conventional square ½’ knobs. After tightening the rod with the correct torque the handle is released and removed from the rack.

Service handle Hercula 02B:

- It supports all gearboxes with rods up to 43 mm in diameter.

- It is characterized by careful execution; the applied materials include stainless, hardened steel and chrome-vanadium steel.

- It enables replacing steering rods without the need to remove the gearbox from the car.

- It has a lifetime manufacturer’s warranty.